Alpha Process – Importance in Shell Mold Making

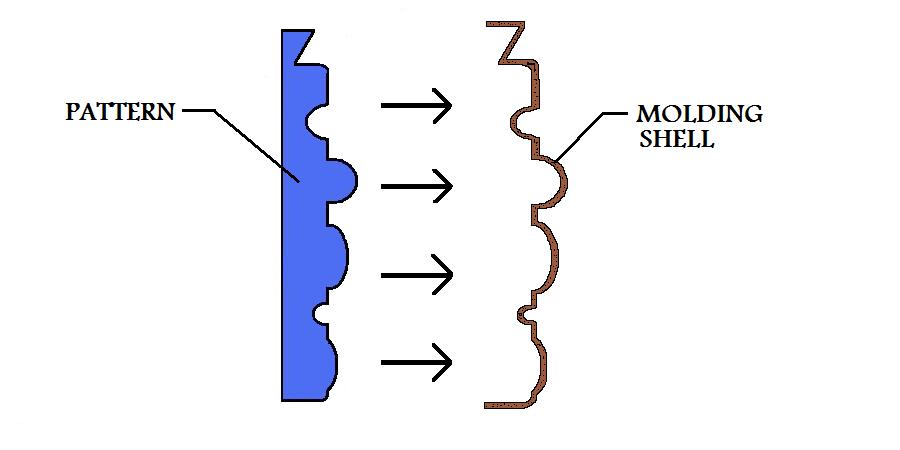

What is Alpha Process? The Alpha Process is a technique used in foundries to make shell molds and cores in an efficient and less expensive way as compared to other processes.

The Alpha process is an extension of the Shell Molding process which uses a special resin coated sand mixture which attains a hard and rigid structure when it is baked with a mold or core pattern. However this material is expensive and difficult to remove from the final casting.

Advantages of Alpha Process: The Alpha Process overcomes this disadvantage by using lesser shell material while providing similarly accurate dimensional tolerances and high quality surface finish. The Alpha process also provides better venting for mold gases which is beneficial for reducing porosity defects and is also much easier to remove from the poured casting.

The reduction in material usage leads to lower costs and the manufacturing time for the molds is also around 30 to 50% faster which makes the process even more economically competitive. For these reasons the Alpha process is regarded as a balanced process which combines many of the desirable qualities of different processes such as investment casting, shell casting, permanent mold and die casting while managing to stay economically attractive.