JIS G3116 Gas cylinder Hot Rolled SG325 Steel

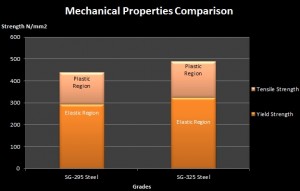

What is SG325 Steels? SG325 steel is a structural hot Rolled steel in the form of plates, sheets & strips for general gas cylinder applications. SG325 is a material grade and designation defined in JIS G 3116 standard. JIS G 3116 is a Japanese material standard for hot Rolled steel plates, sheets, strips for general gas cylinder usage. SG325 has greater elastic region & tensile strength as compare to SG295 steel.

Dimensional Characteristics of SG325 Steels: The applicable thickness for this SG325 material as defined in the JIS 3116 starts from 1.5 mm to 20 mm. The width is normally from 1000 mm to 2500 mm.

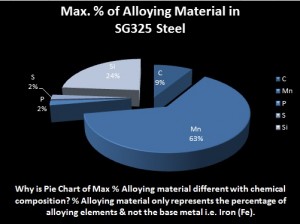

The Chemical Composition of SG325 Steels: JIS G 3116 defines the chemical composition of SG325 steels as under:

Maximum percentage of Carbon (C) is 0.20.

Maximum percentage of Silicon (Si) is 0.55.

Maximum percentage of Manganese (Mn) is 1.5.

Maximum percentage of Phosphorous (P) is 0.040.

Maximum percentage of Sulphur (S) is 0.040.

Remaining is iron (Fe) percentage and with few negligible impurities.

Mechanical Properties of SG325 Steels: The tensile strength of the SG325 Steels is expressed in Newton per millimeters and it must be at-least 490 N/mm2 (MPa). The yield strength is minimum 325 N/mm2 (MPa). The minimum percentage ranges for elongation is 22%.

SG295 steel comparison with this grade of SG325 material will show how it differs with lower strength steel in chemical composition & mechanical properties. Application of this kind of steel is in making gas cylinders.